ANSI Z87+ vs. MIL-PRF-32432A

Share

Understanding the Differences: ANSI Z87+ vs. MIL-PRF-32432A Ballistic Protection Standards

When it comes to ballistic protection for eyewear, two key standards often come into play: ANSI Z87+ and MIL-PRF-32432A. While both standards aim to ensure safety, they cater to different needs and environments. Let’s break down the differences between these two standards to help you make an informed decision.

ANSI Z87+ Standard

The ANSI Z87+ standard is a civilian safety standard developed by the American National Standards Institute (ANSI). It focuses on providing impact protection for everyday use in various industrial and occupational settings. Here are some key points:

- Impact Resistance: ANSI Z87+ eyewear is tested to withstand impacts from objects like flying debris, particles, and small tools. It’s suitable for general industrial use.

- Testing Method: The standard involves dropping a 0.25-inch (6.4 mm) steel ball from a height of 150 feet per second (approximately 46 meters per second) onto the lens to ensure it doesn’t crack, shatter, or dislodge.

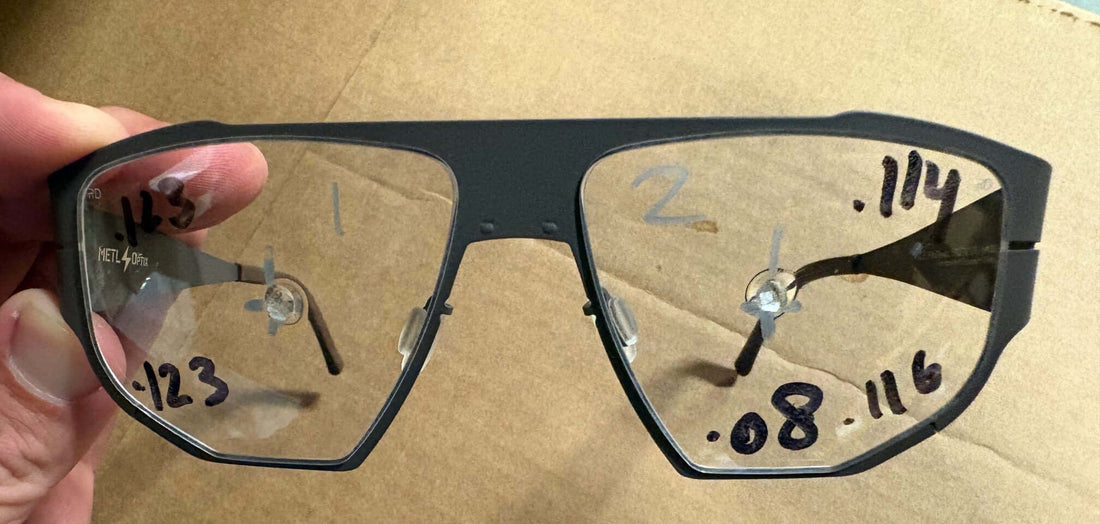

- Marking: Eyewear that meets the ANSI Z87+ standard will have a “Z87+” marking on the lens and frame.

MIL-PRF-32432A Standard

The MIL-PRF-32432A standard is a military specification developed by the U.S. Department of Defense. It’s designed to provide ballistic protection for military personnel in combat situations. Here are some key points:

- Ballistic Fragmentation Resistance: MIL-PRF-32432A eyewear is tested to withstand high-velocity impacts from fragments and projectiles encountered in combat. It’s much more stringent than the ANSI Z87+ standard.

- Testing Method: The standard involves firing a 0.15-caliber (3.81 mm) projectile at a velocity of 700 to 725 feet per second (approximately 213 to 220 meters per second) at the eyewear.

- Additional Requirements: Besides impact resistance, MIL-PRF-32432A also requires that the eyewear be functional, reasonably comfortable, free of bright colors or distracting designs, and able to be disinfected.

Key Differences

- Impact Energy: The MIL-PRF-32432A standard produces approximately 7 times more impact energy than the ANSI Z87+ standard. This means that MIL-PRF-32432A eyewear offers superior protection in high-risk environments.

- Use Case: ANSI Z87+ is suitable for general industrial and occupational use, while MIL-PRF-32432A is specifically designed for military and tactical applications.

- Testing Rigor: The testing methods for MIL-PRF-32432A are much more rigorous and stringent compared to ANSI Z87+.

Conclusion

Choosing the right ballistic eyewear depends on your specific needs and environment. If you’re looking for everyday industrial safety, ANSI Z87+ eyewear will provide adequate protection. However, if you’re in a military or tactical setting where high-velocity impacts are a concern, MIL-PRF-32432A eyewear is the way to go.

Understanding these differences can help you select the appropriate eyewear to ensure your safety and performance. Whether you’re on the job or in the field, having the right protection is crucial.